Introduction

Understanding the significance of infill sand is crucial for anyone aiming to improve their artificial grass experience. This material, while seemingly simple, plays a vital role in preserving the integrity and appearance of synthetic turf. It provides essential benefits such as:

- Stability

- Safety

- Temperature control

With various types of infill available and best practices to consider, how can one ensure they are making informed choices tailored to their specific needs? By exploring the nuances of infill sand, readers can appreciate its importance and gain insights into best practices for installation and maintenance, ultimately leading to a lush and enduring lawn.

Understand Infill Sand: Definition and Purpose

Infill sand is a crucial granular material that is positioned between the blades of artificial grass, fulfilling several important functions. Its primary role is to provide stability and support, keeping the grass fibers upright and preventing matting, which ensures a consistently lush appearance. Additionally, this material absorbs impact, enhancing safety for activities on the surface, particularly in playgrounds and sports fields. It also plays a vital role in temperature control, helping to keep the grass cooler during warm weather, which is crucial for maintaining a pleasant surface for users.

The importance of infill sand as fill material cannot be overstated, as it directly influences the durability and efficiency of synthetic grass systems. For instance, utilizing the recommended 1-2 pounds of material per square foot not only supports the grass fibers but also helps prevent rippling in elevated temperatures, ensuring that the lawn remains visually appealing throughout the year. Moreover, granular material is often more economical than alternatives such as Zeolite and MellowFill, making it an attractive option for homeowners looking to maintain their synthetic lawns without overspending.

Real-world examples illustrate the effectiveness of filler material in enhancing synthetic turf performance. Certain kiln-dried materials are specifically designed to inhibit weed growth, preserving the aesthetic appeal of lawns. Additionally, the fire-resistant properties of granular material enhance safety, particularly for synthetic lawns made from nylon or polyethylene, which can pose fire risks. Overall, understanding the roles and benefits of fill material is crucial for anyone involved in the installation or maintenance of synthetic grass, as it ensures optimal performance and longevity of the grass system.

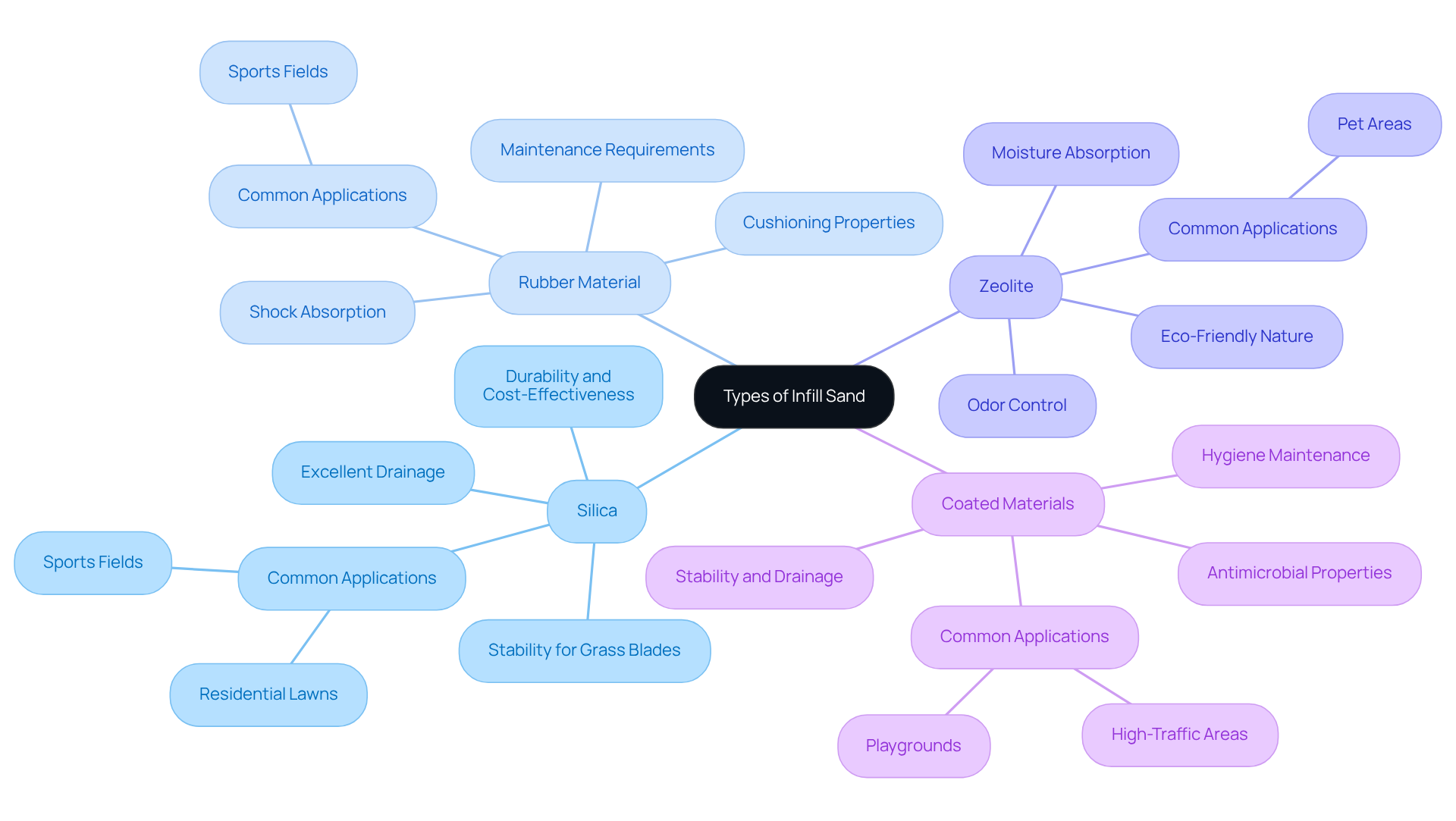

Explore Different Types of Infill Sand and Their Applications

In artificial turf installations, infill sand is essential, and various types are available, each providing unique benefits tailored to specific applications.

-

Silica: This is the most commonly used filler, known for its durability and cost-effectiveness. Silica excels in providing excellent drainage and stability, ensuring that grass blades remain upright and functional. Its popularity spans residential lawns and sports fields alike. Customers, such as Dick Bryant, have found Hall Turf’s recommendations for silica sand to be perfectly suited to their needs, showcasing Brock’s expertise in selecting the right materials.

-

Rubber Material: Frequently used in sports fields, rubber material is recognized for its exceptional shock absorption and cushioning properties. This makes it ideal for high-impact areas where safety and comfort are paramount, although it may require more maintenance compared to other options. Scott Sachse’s experience with Hall Turf highlights the professionalism and quality of installation, ensuring that rubber material is applied effectively.

-

Zeolite: Particularly beneficial for pet areas, zeolite infill effectively controls odors and absorbs moisture, contributing to a cleaner environment. Its eco-friendly nature enhances the overall performance of the grass, making it a preferred choice for pet owners. Hall Turf’s attention to detail ensures that pet areas are not only functional but also pleasant for both pets and their owners.

-

Coated Materials: These specially treated substances often incorporate antimicrobial properties, making them suitable for playgrounds and high-traffic areas. They help maintain hygiene while providing the necessary stability and drainage for active environments. Les Boatright’s satisfaction with Hall Turf’s work reflects the company’s commitment to delivering high-quality solutions for various applications.

Choosing the appropriate material type, such as infill sand, depends on the intended use of the turf, environmental factors, and budget considerations. For instance, silica material is frequently preferred for its cost-effectiveness and ease of maintenance, while rubber filler is selected for its cushioning advantages in athletic applications. Understanding these differences is vital for enhancing the performance and longevity of synthetic grass installations.

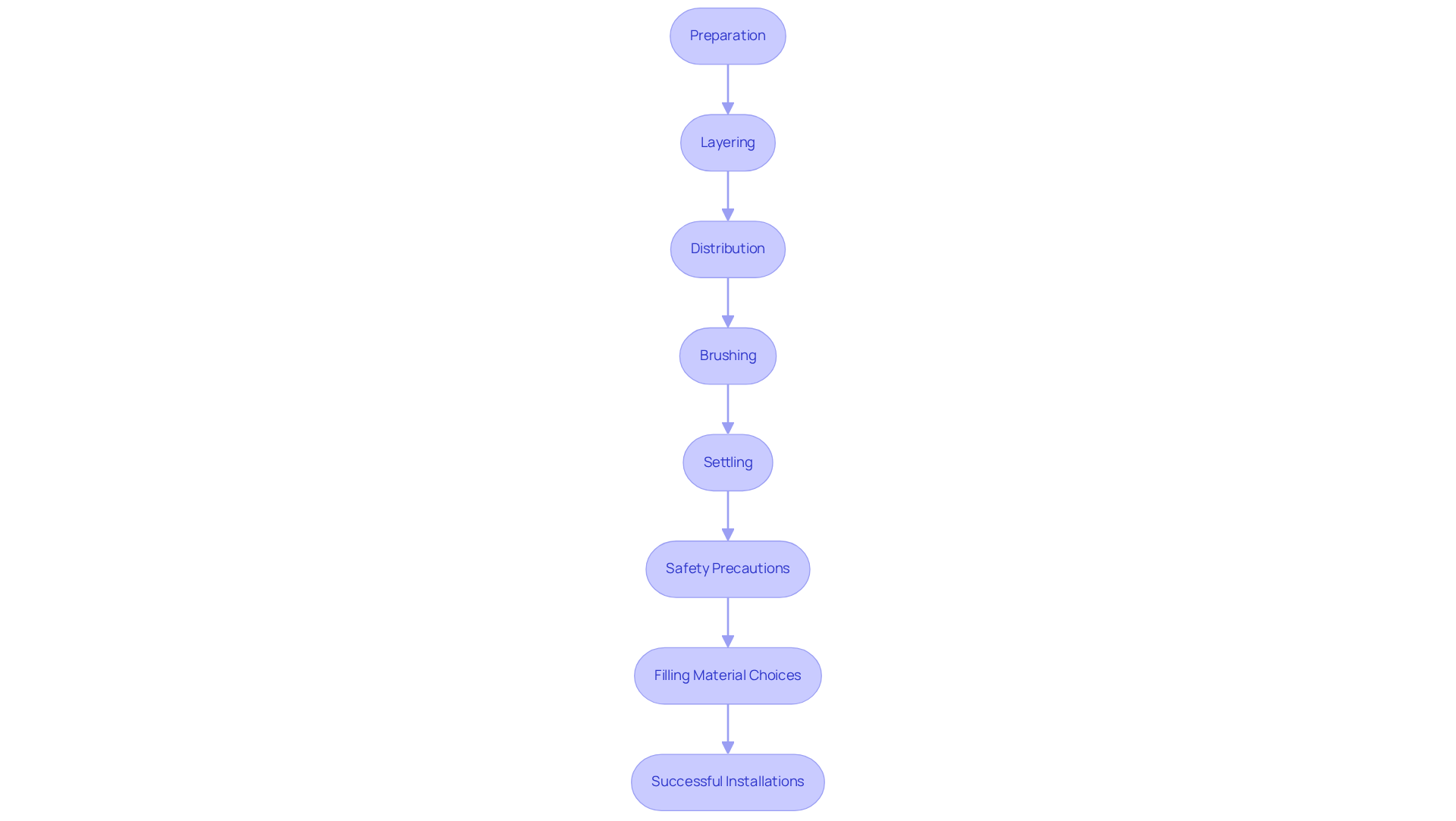

Implement Best Practices for Installing Infill Sand

To achieve optimal results when installing infill sand for artificial grass, follow these best practices:

-

Preparation: Ensure the turf is properly installed and the surface is clean. Utilize a power broom to raise the grass fibers, creating an ideal setting for material application.

-

Layering: Begin with a base layer of 1-2 pounds of material per square foot. This technique prevents compaction and promotes better distribution throughout the grass.

-

Distribution: Employ a drop spreader for even application of the material. This method minimizes waste and ensures that all areas of the turf receive adequate coverage.

-

Brushing: After applying the filler, use a power broom or stiff brush to work the material into the grass fibers. This step is crucial for ensuring the blades stand upright and maintain a natural appearance.

-

Settling: Lightly water the area to assist in positioning the material. This not only reduces dust but also enhances the overall look of the turf.

-

Safety Precautions: Keep children and pets away from the work area during the application process. It is advisable to wear goggles and gloves to protect yourself while handling filler materials.

-

Filling Material Choices: Consider using high-quality filling materials such as infill sand, Envirofill, or Crumb Rubber, which provide additional benefits like improved drainage and safety.

-

Successful Installations: Look for examples of effective grass installations that have utilized these layering techniques to understand their practical application.

By adhering to these steps, you will significantly enhance both the performance and visual appeal of your synthetic grass installation.

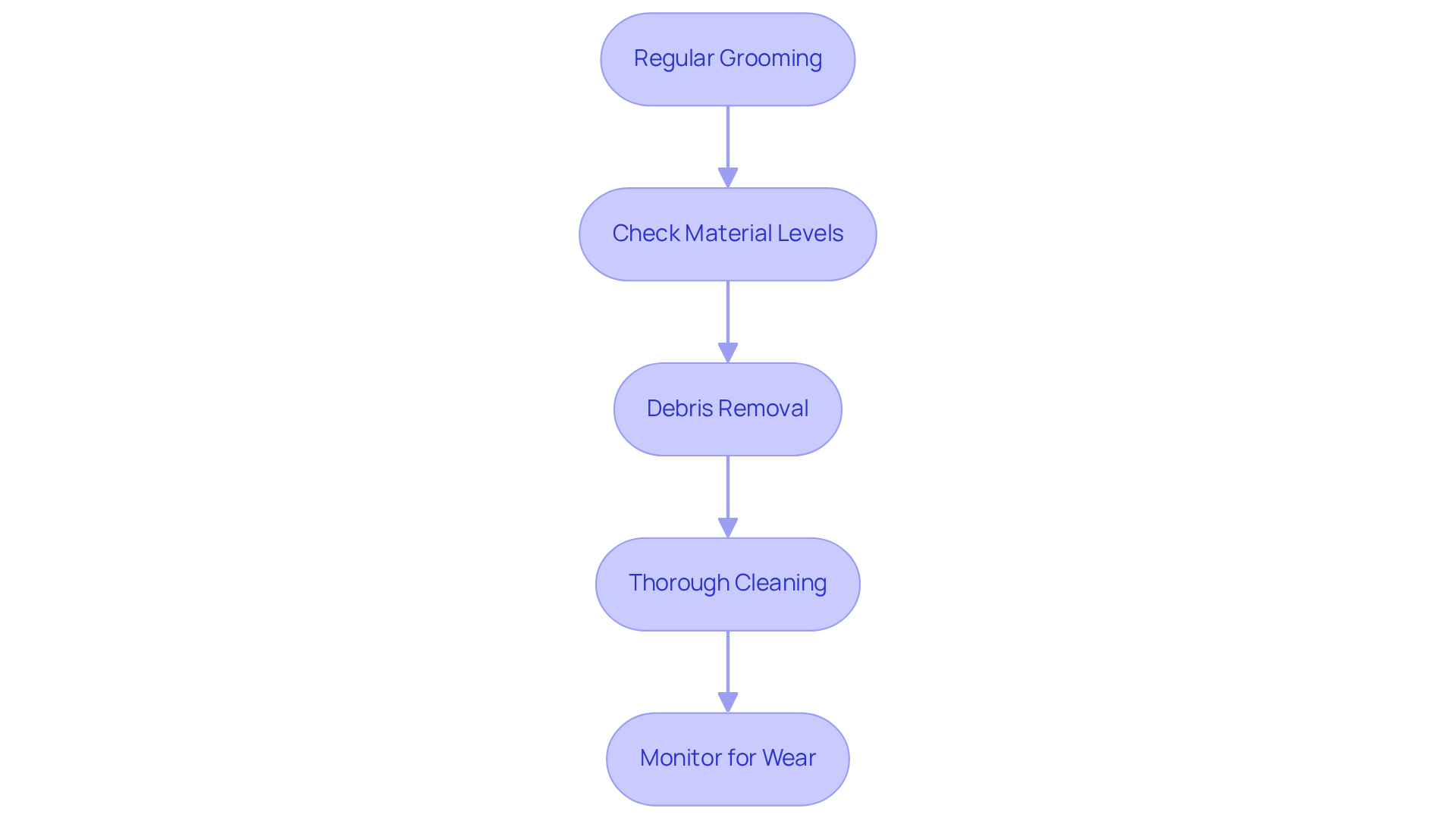

Maintain Infill Sand for Longevity and Performance

To ensure the longevity and optimal performance of infill sand in artificial turf, it is essential to follow these best practices:

- Regular Grooming: Groom the turf at least once a month using a power broom or stiff brush. This process raises the grass fibers and redistributes the material, preventing compaction and preserving a natural appearance.

- Check Material Levels: Regularly inspect the material levels to confirm they are within the recommended range of one to two pounds per square foot. Replenish infill sand as necessary to maintain the desired depth and performance. Inadequate infill sand can cause the blades to flatten, resulting in an unnatural appearance and decreased durability.

- Debris Removal: Consistently eliminate debris, leaves, and pet waste from the grass. This practice prevents organic matter from breaking down and adversely affecting the material’s effectiveness.

- Thorough Cleaning: Arrange for a yearly thorough cleaning of the surface, which may involve rinsing the material and grass with water to remove dust and pollutants. This ensures a fresh and spotless area. It is crucial as the material can gradually dissipate over time due to weather conditions and foot traffic.

- Monitor for Wear: Regularly inspect the grass for signs of wear or matting. If the grass fibers begin to flatten, it may indicate the need for additional infill sand or professional maintenance. Employing expert services can guarantee comprehensive cleaning and upkeep, improving the durability of your grass.

By implementing these maintenance practices, you can keep your artificial turf in excellent condition, enhancing its durability and aesthetic appeal for years to come.

Conclusion

Infill sand is crucial for the performance and maintenance of artificial grass, providing stability, safety, and aesthetic appeal. Understanding its various functions – from supporting grass fibers to regulating temperature – highlights the importance of this material in achieving a lush, long-lasting lawn. Choosing the right infill sand not only boosts the durability of synthetic turf but also enhances the user experience in both residential and recreational settings.

Key insights into the types of infill sand – such as silica, rubber, zeolite, and coated materials – underscore the necessity of selecting the appropriate material based on specific needs and applications. Best practices for installation, including thorough preparation, proper layering, and ongoing maintenance, are essential for maximizing the benefits of infill sand. Regular grooming, debris removal, and monitoring material levels are vital to keeping artificial turf in optimal condition, thereby preserving its functionality and appearance.

Ultimately, investing in the right infill sand and following best practices for installation and maintenance can significantly improve the longevity and performance of artificial grass. By adopting these strategies, one can achieve not only a visually appealing lawn but also a safe and enjoyable environment for all users. For anyone involved in artificial grass installations, understanding and implementing these practices is key to achieving the best results.

Frequently Asked Questions

What is infill sand and what is its purpose?

Infill sand is a granular material placed between the blades of artificial grass to provide stability and support, keeping the grass fibers upright and preventing matting. It also absorbs impact for safety, aids in temperature control, and helps maintain a lush appearance.

How does infill sand enhance safety on artificial grass surfaces?

Infill sand absorbs impact, which enhances safety during activities on the surface, particularly in playgrounds and sports fields.

Why is temperature control important for artificial grass, and how does infill sand help?

Temperature control is important for maintaining a pleasant surface for users, especially in warm weather. Infill sand helps keep the grass cooler, contributing to user comfort.

What is the recommended amount of infill sand to use per square foot?

The recommended amount of infill sand is 1-2 pounds per square foot, which supports the grass fibers and helps prevent rippling in elevated temperatures.

How does infill sand compare to other fill materials like Zeolite and MellowFill?

Infill sand is often more economical than alternatives such as Zeolite and MellowFill, making it an attractive option for homeowners looking to maintain synthetic lawns without overspending.

What are some additional benefits of using infill sand in synthetic turf?

Infill sand can inhibit weed growth, preserve the aesthetic appeal of lawns, and has fire-resistant properties that enhance safety, especially for synthetic lawns made from nylon or polyethylene.

Why is it important to understand the roles and benefits of infill sand?

Understanding the roles and benefits of infill sand is crucial for anyone involved in the installation or maintenance of synthetic grass, as it ensures optimal performance and longevity of the grass system.