Introduction

Ensuring the safety and durability of playground installations is increasingly critical as communities prioritize safe recreational spaces for children. By implementing best practices in safety standards, material selection, site preparation, and ongoing maintenance, playground operators can create environments that protect children while enhancing community trust and satisfaction.

However, navigating the complexities of playground installation can be challenging due to numerous regulations and material options. How can operators ensure compliance and longevity in their installations? Exploring these best practices reveals essential insights that can significantly reduce injury risks and extend the life of playground equipment.

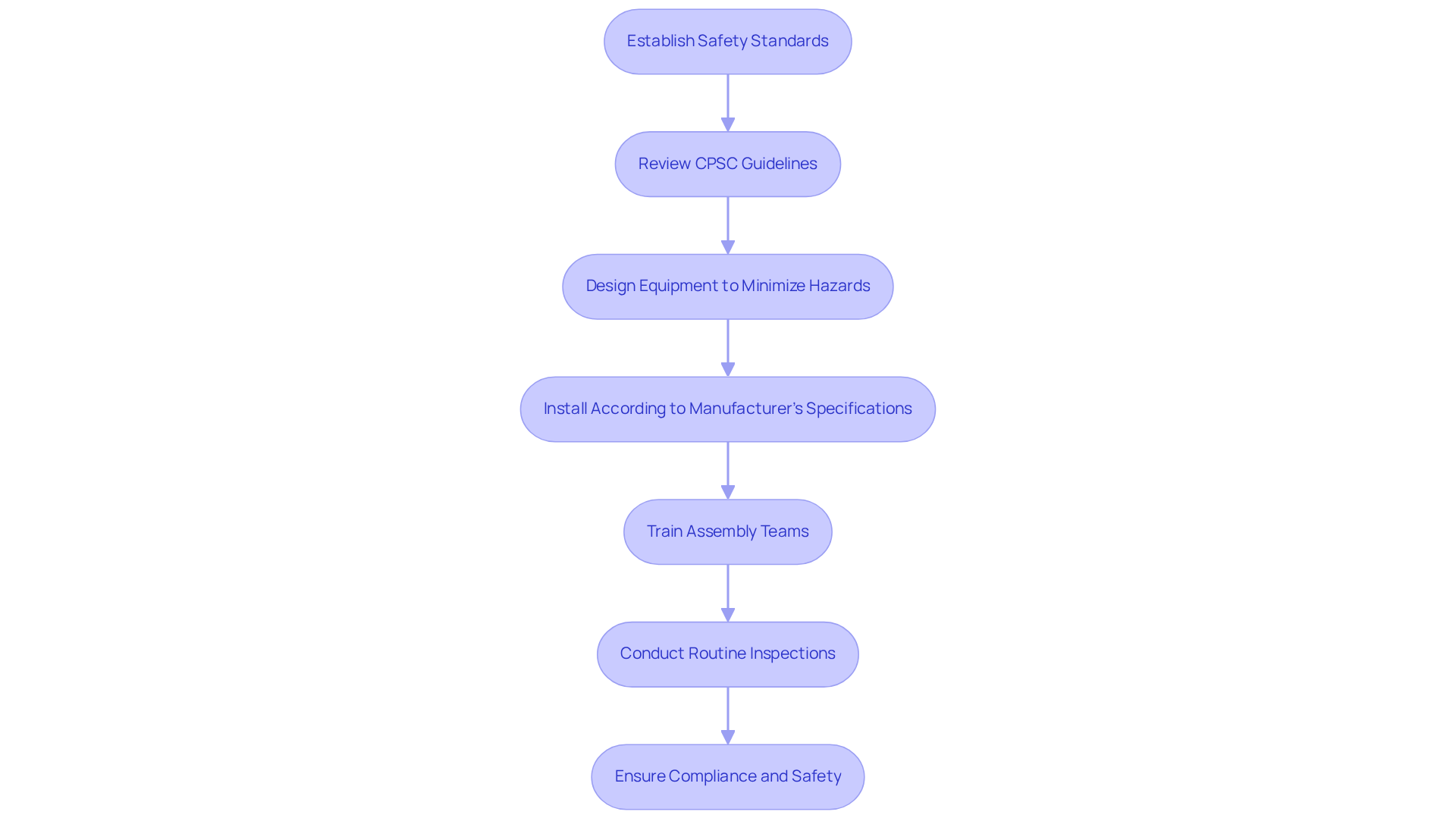

Establish Safety Standards for Playground Installation

To ensure the security of recreational equipment, adhering to established safety guidelines is essential. The U.S. Consumer Product Safety Commission (CPSC) provides comprehensive guidelines that outline the necessary safety measures for recreational equipment. These guidelines include specifications for equipment design, installation, and maintenance. For example, playground equipment should be designed to minimize hazards, such as sharp edges and entrapment points. Additionally, it is crucial to confirm that the equipment for the austin playground installation is installed according to the manufacturer’s specifications and complies with the ASTM F1487 criteria for performance.

Consistent training for assembly teams on these guidelines can enhance compliance with regulations and reduce liability risks. Implementing these protective measures not only safeguards children but also builds trust among parents and communities, thereby strengthening the company’s reputation. Statistics indicate that adherence to protective protocols significantly reduces the incidence of injuries in play areas, highlighting the critical role of compliance in creating safe recreational environments. Studies show that compliant recreational areas experience up to a 40% decrease in injury rates compared to non-compliant setups.

Experts emphasize the importance of these criteria, with child protection advocate Dr. Jane Smith stating, ‘Following protective protocols is not merely a guideline; it’s a commitment to safeguarding our children.’ Recent projects, including the austin playground installation at the newly refurbished recreational area at Lowell Brandt Park, illustrate the significance of compliance by incorporating modern protective features that meet current standards. By avoiding common pitfalls, such as neglecting routine maintenance and failing to conduct inspections, companies can ensure that their recreational areas remain secure and enjoyable for all users.

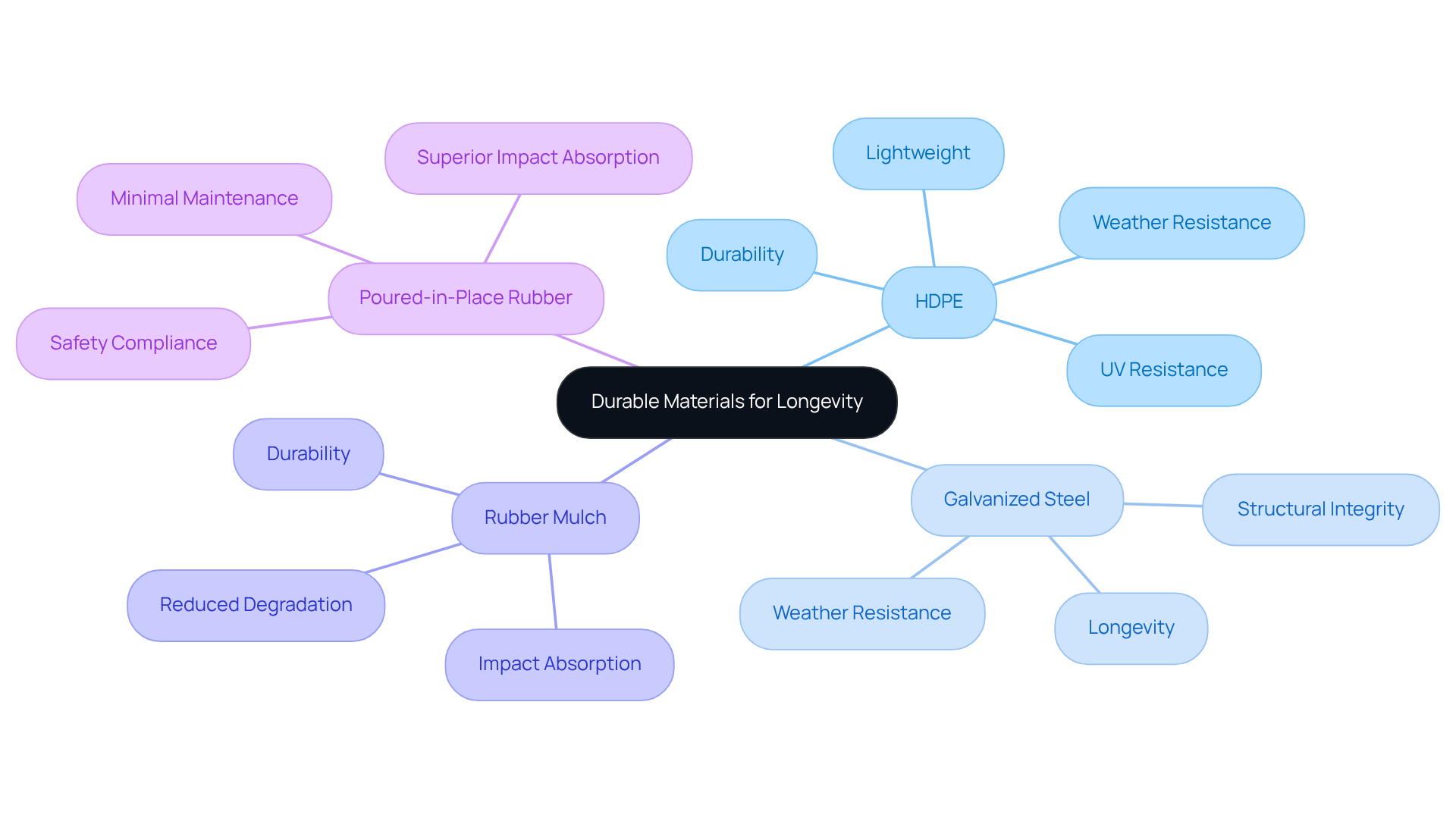

Choose Durable Materials for Longevity

Selecting durable materials is essential for ensuring the longevity and safety of recreational area installations. High-density polyethylene (HDPE) and galvanized steel are particularly recommended due to their exceptional resistance to weathering and wear. HDPE is recognized for its durability; it is lightweight yet robust, making it ideal for various recreational equipment. Its resistance to fading and cracking helps maintain the aesthetic appeal of recreational areas over time. Conversely, galvanized steel offers strong structural integrity, making it a preferred choice for swings, slides, and climbing structures.

For surfacing, options such as rubber mulch or poured-in-place rubber provide superior impact absorption, significantly reducing the risk of injuries. These materials are less prone to degradation compared to traditional wood chips, ensuring a safer play environment. Additionally, incorporating UV-resistant materials can prevent fading and deterioration from sun exposure, further enhancing the lifespan of the play area.

Investing in high-quality materials minimizes maintenance costs and extends the lifespan of the equipment, ultimately creating a safer and more enjoyable play area for children.

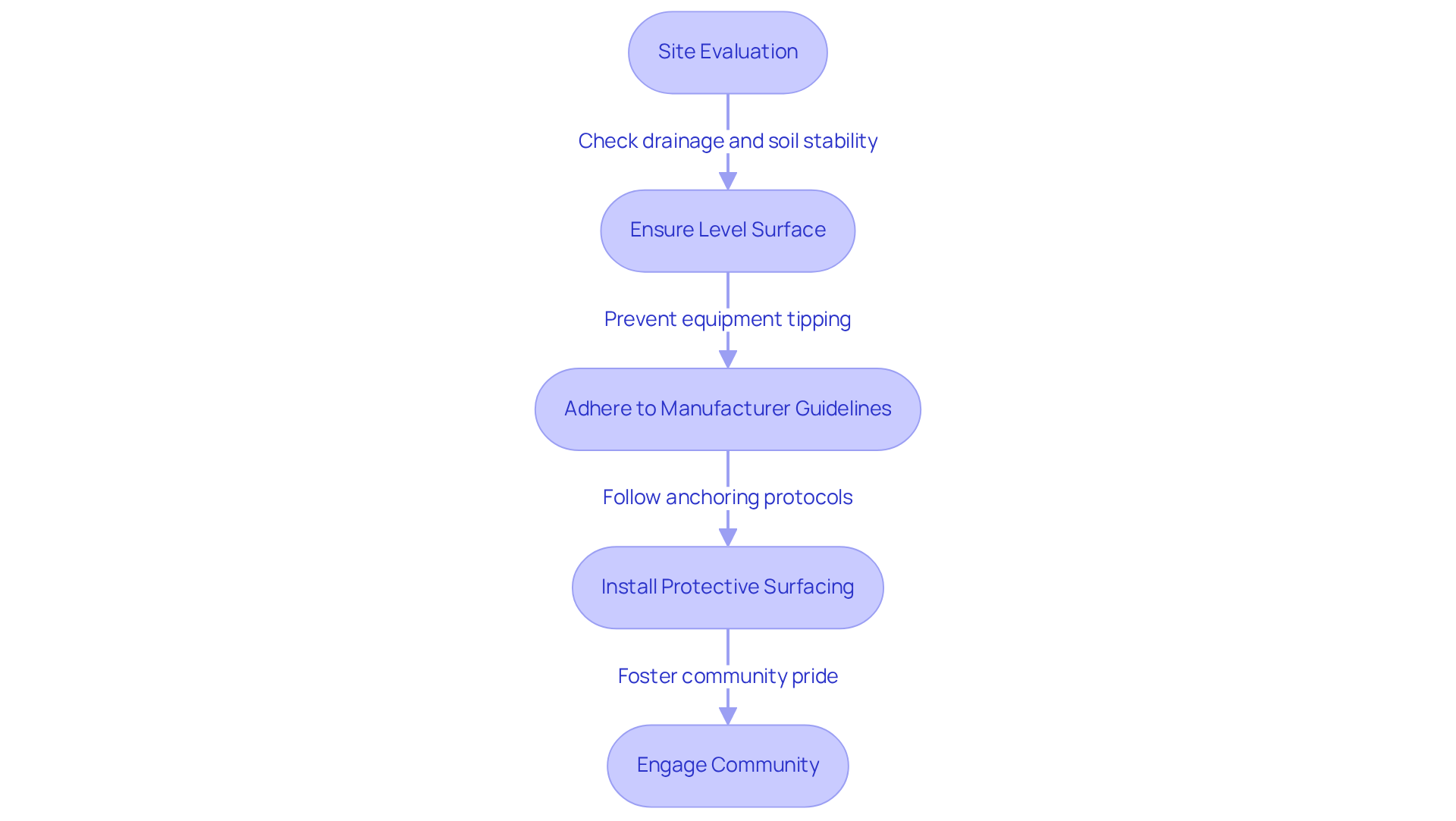

Implement Proper Site Preparation and Installation Techniques

Efficient site preparation and assembly methods are crucial for ensuring the safety and longevity of austin playground installation. Before the austin playground installation, a comprehensive evaluation of the site is necessary, focusing on key factors such as drainage, soil stability, and accessibility. A level surface is vital for austin playground installation to prevent equipment tipping and to facilitate proper drainage; even a slight slope of 1-2% can significantly enhance water runoff and prevent pooling. For instance, one inch of rain can lead to over 27,000 gallons of water on a 1-acre playground, highlighting the need for effective drainage solutions.

During the setup of the austin playground installation, it is essential to strictly adhere to manufacturer guidelines for anchoring and securing equipment. Utilizing concrete footings for larger structures, for example, greatly improves stability. Additionally, austin playground installation involves installing protective surfacing at the correct depth and ensuring it is free from debris, which are critical steps in reducing injury risks. Routine training for assembly teams on these best practices not only maintains high standards but also ensures compliance with regulations, ultimately fostering a secure play environment for children during the austin playground installation.

Engaging the community in park constructions can further strengthen the sense of connection and pride among neighbors, transforming the area into a valued local resource. It is also important to recognize common mistakes in the austin playground installation, such as neglecting adequate drainage or failing to adhere to protective protocols, as these oversights can jeopardize the overall safety and enjoyment of the play space.

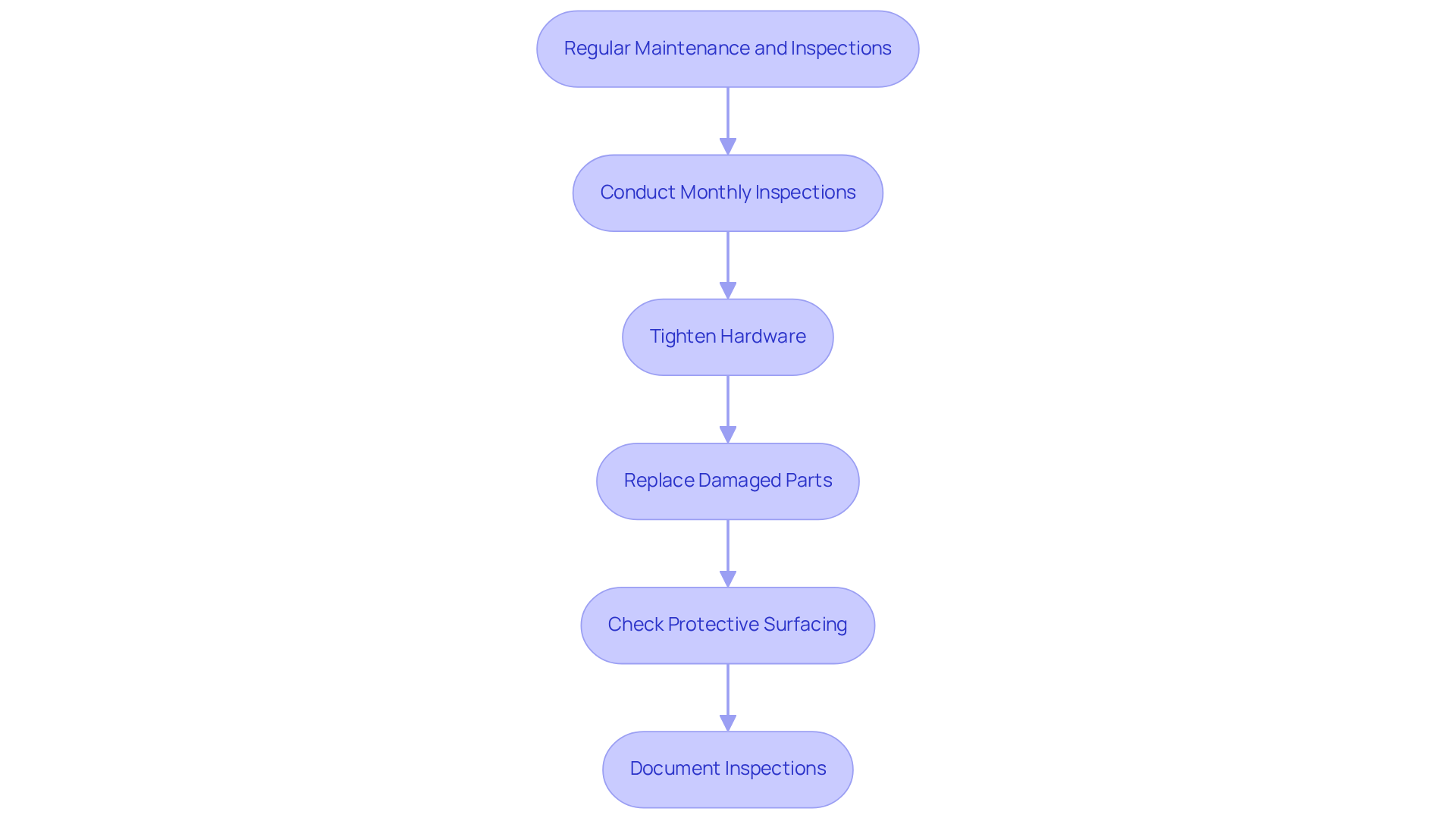

Conduct Regular Maintenance and Inspections

Regular maintenance and inspections are crucial for ensuring the safety and longevity of Austin playground installations. A routine inspection schedule facilitates the early detection of potential hazards, such as loose bolts, splintered wood, or worn-out surfacing. The CPSC guidelines recommend conducting inspections at least monthly, with more frequent checks during periods of heavy use.

Maintenance tasks should include:

- Tightening hardware

- Replacing damaged parts

- Ensuring that protective surfacing remains intact and at the appropriate depth

Additionally, documenting inspections and maintenance tasks provides important records for liability purposes and demonstrates a commitment to safety.

Significantly, over 200,000 children are injured in recreational areas each year, underscoring the need for proactive safety measures. Allocating funds for inspections and maintenance is essential to ensure that recreational areas remain secure and compliant with regulations. It is advisable to designate a responsible individual or department for inspections to enhance accountability in maintenance practices.

By prioritizing maintenance, playground operators can foster a safer environment for children and improve the overall user experience during the Austin playground installation.

Conclusion

Ensuring the safety and durability of playground installations in Austin is essential for protecting children and fostering community trust. By adhering to established safety standards and implementing best practices, playground operators can create environments that are both secure and engaging.

Following guidelines from organizations like the U.S. Consumer Product Safety Commission and ASTM standards is crucial. Using high-quality materials such as HDPE and galvanized steel significantly enhances the longevity of playground equipment. Moreover, effective site preparation and installation techniques are vital in preventing hazards. Routine inspections and maintenance further ensure ongoing safety and compliance with regulations.

Investing in these best practices transcends mere regulatory compliance; it prioritizes the well-being of children and the enjoyment of families within the community. By adopting a proactive approach to playground safety and durability, stakeholders can develop vibrant, secure recreational spaces that endure over time and become cherished local resources.

Frequently Asked Questions

What are the main safety standards for playground installation?

The main safety standards for playground installation are outlined by the U.S. Consumer Product Safety Commission (CPSC) and include guidelines for equipment design, installation, and maintenance to minimize hazards such as sharp edges and entrapment points.

What specific performance criteria must playground equipment meet?

Playground equipment must be installed according to the manufacturer’s specifications and comply with the ASTM F1487 criteria for performance.

How can consistent training for assembly teams impact playground safety?

Consistent training for assembly teams on safety guidelines can enhance compliance with regulations and reduce liability risks, leading to safer recreational environments.

What benefits do protective measures provide in playgrounds?

Implementing protective measures safeguards children, builds trust among parents and communities, and strengthens the company’s reputation.

How does adherence to safety protocols affect injury rates in playgrounds?

Adherence to protective protocols can significantly reduce the incidence of injuries in play areas, with compliant recreational areas experiencing up to a 40% decrease in injury rates compared to non-compliant setups.

What recent project exemplifies the importance of compliance in playground installation?

The austin playground installation at the newly refurbished recreational area at Lowell Brandt Park illustrates the significance of compliance by incorporating modern protective features that meet current standards.

What common pitfalls should companies avoid in playground maintenance?

Companies should avoid neglecting routine maintenance and failing to conduct inspections to ensure that recreational areas remain secure and enjoyable for all users.