Introduction

Selecting the right aggregate is crucial for the installation of artificial grass, yet many homeowners underestimate its importance. Understanding the different types of aggregates – such as crushed stone, decomposed granite, and sand – can significantly enhance the durability and appearance of synthetic lawns. However, navigating common pitfalls during installation poses a challenge that can lead to costly mistakes and unsatisfactory results. To ensure a flawless installation and long-lasting beauty for artificial grass, what essential tips should be considered?

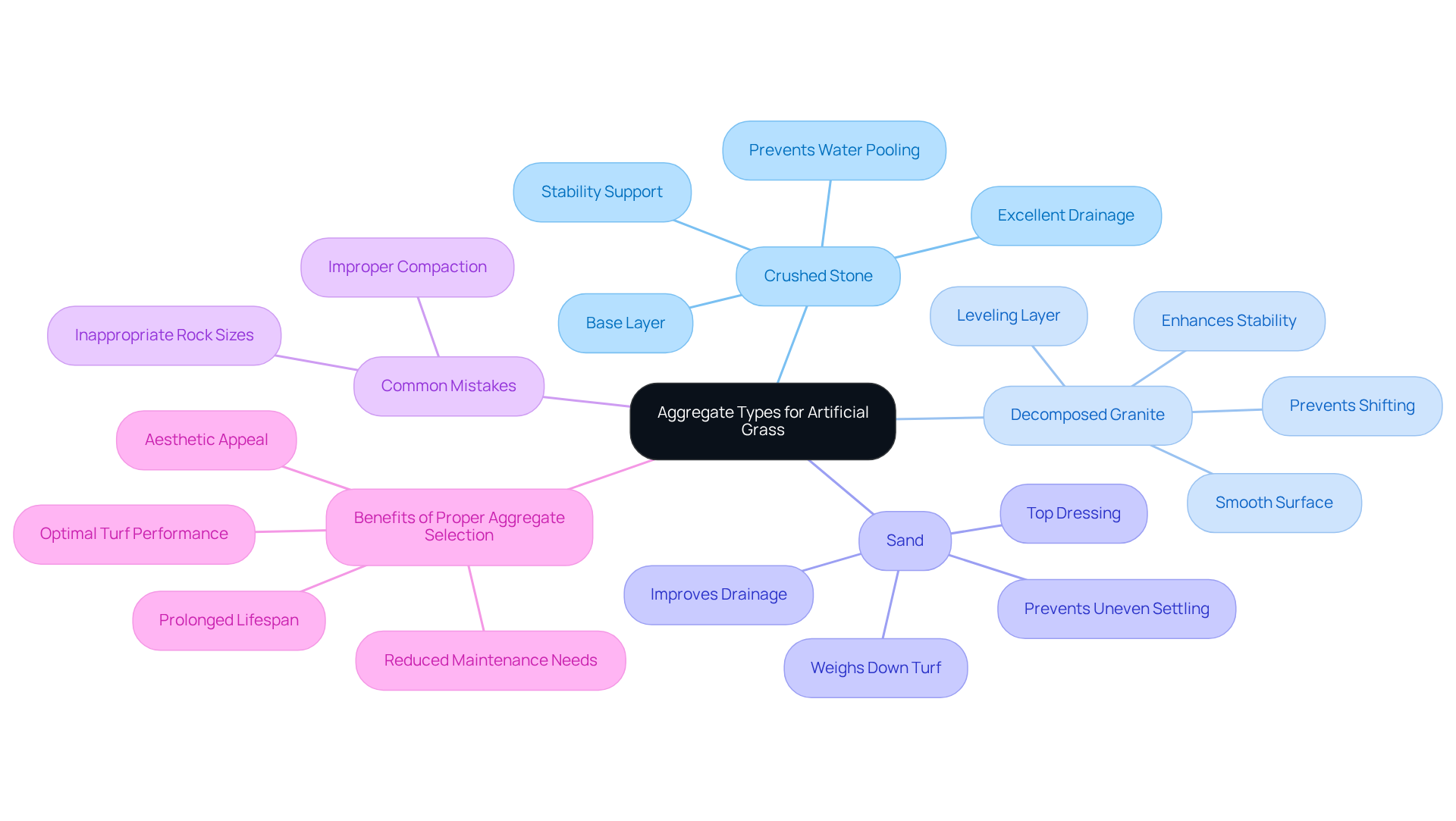

Understand Aggregate Types for Artificial Grass

When installing artificial grass, it is crucial to select the right aggregate for artificial grass. The most common types include crushed stone, decomposed granite, and sand, each serving a specific purpose.

-

Crushed Stone is typically used as a base layer, providing excellent drainage and stability. A popular choice is 3/4 inch crushed granite or limestone, which allows water to pass through while supporting the grass. Effective drainage systems, facilitated by crushed stone, enable water to move freely through the base without pooling or waterlogging, thus preventing long-term issues with the turf.

-

Decomposed Granite serves as a leveling layer on top of the crushed stone. This finer material compacts well, offering a smooth surface for the grass and enhancing overall stability. Proper compaction of the sub-base is essential to prevent shifting over time, ensuring a visually appealing finish.

-

Sand is often used as a top dressing, helping to weigh down the turf and improve drainage. It is vital to select silica sand specifically intended for synthetic turf, as it fills spaces between larger aggregates, preventing uneven settling and maintaining a tidy surface for long-term upkeep.

Common mistakes to avoid when preparing the base include using inappropriate rock sizes and failing to compact materials properly. These pitfalls can lead to instability and drainage issues, undermining the effectiveness of the installation.

Choosing the right aggregate for artificial grass not only enhances the installation process but also ensures optimal turf performance over time, reducing maintenance needs and prolonging its lifespan. Homeowners can enjoy a lush, green lawn year-round by making informed choices about their aggregate materials.

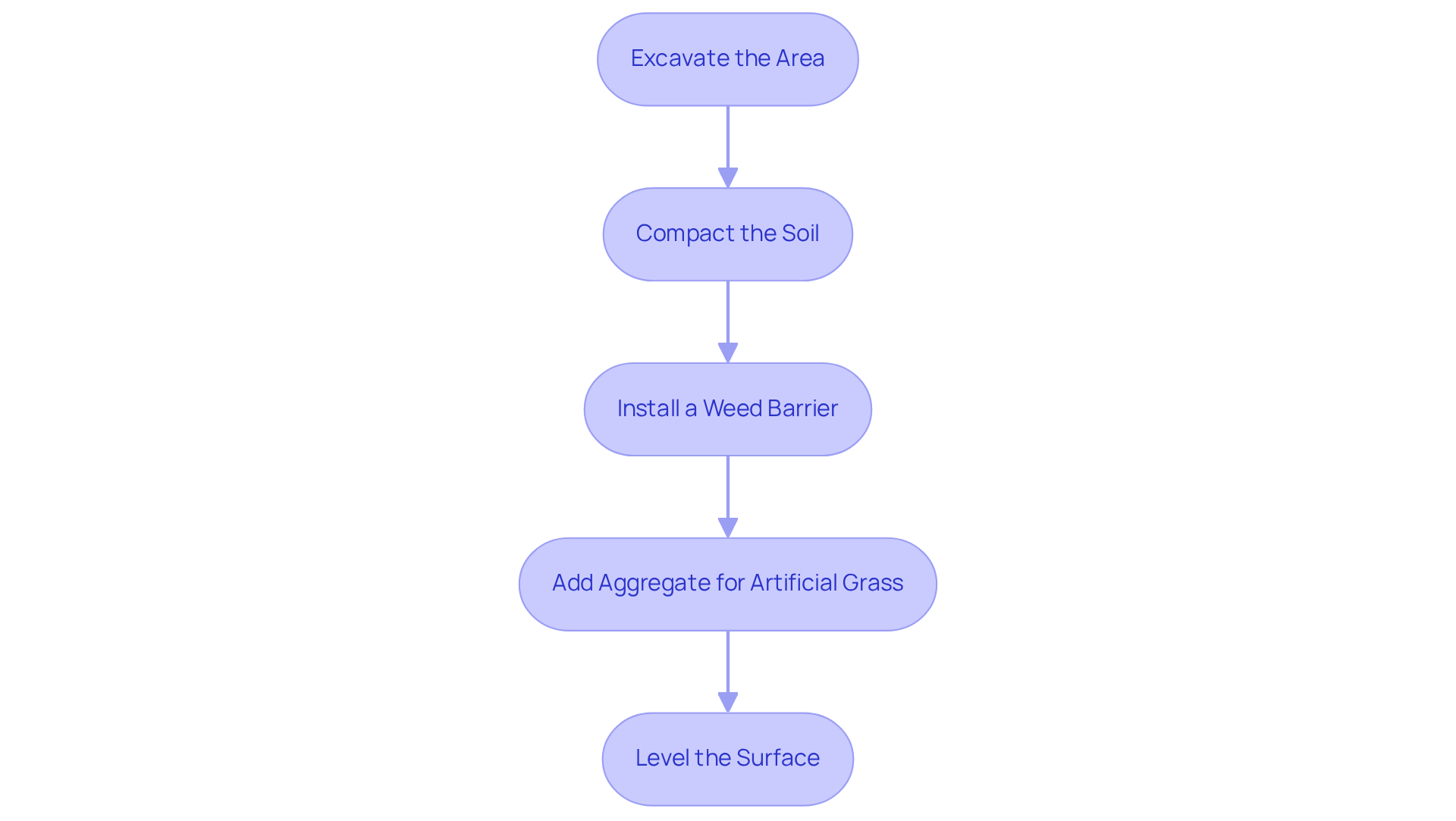

Prepare the Base for Optimal Installation

To achieve a successful artificial grass installation with Hall Turf, it is essential to follow these steps for base preparation:

- Excavate the Area: Begin by removing existing grass, roots, and debris to a depth of 3-4 inches. This step ensures that the base is free from organic material that could decompose and lead to uneven settling.

- Compact the Soil: Utilize a plate compactor to compact the soil, creating a firm foundation. Lightly mist the area with water during compaction to help bind particles and enhance stability. This step is crucial for preventing future settling.

- Install a Weed Barrier: Lay down a weed barrier fabric to prevent weeds from growing through the turf. Overlap seams of the weed barrier by 6-12 inches and secure it with 20D nails or landscape staples. This barrier should be placed over the compacted soil before adding the aggregate.

- Add aggregate for artificial grass: Spread a layer of crushed stone or gravel, ensuring it is evenly distributed. Compact this layer thoroughly to create a stable base. It is important to maintain a slight slope of 1-2% for drainage away from structures to prevent water accumulation.

- Level the Surface: Use a rake to level the surface, ensuring it is smooth and even. This step is vital for achieving a professional-looking finish. Additionally, remove all dirt and debris from the surface of the weed barrier before laying the turf.

By following these steps, you create a solid foundation that supports the grass and enhances its longevity. Homeowners can trust Hall Turf’s expertise, as evidenced by satisfied customers who commend the professionalism and attention to detail provided by Brock and his team. Secure the turf around the perimeter using galvanized steel stakes or turf nails every 4-6 inches to prevent shifting.

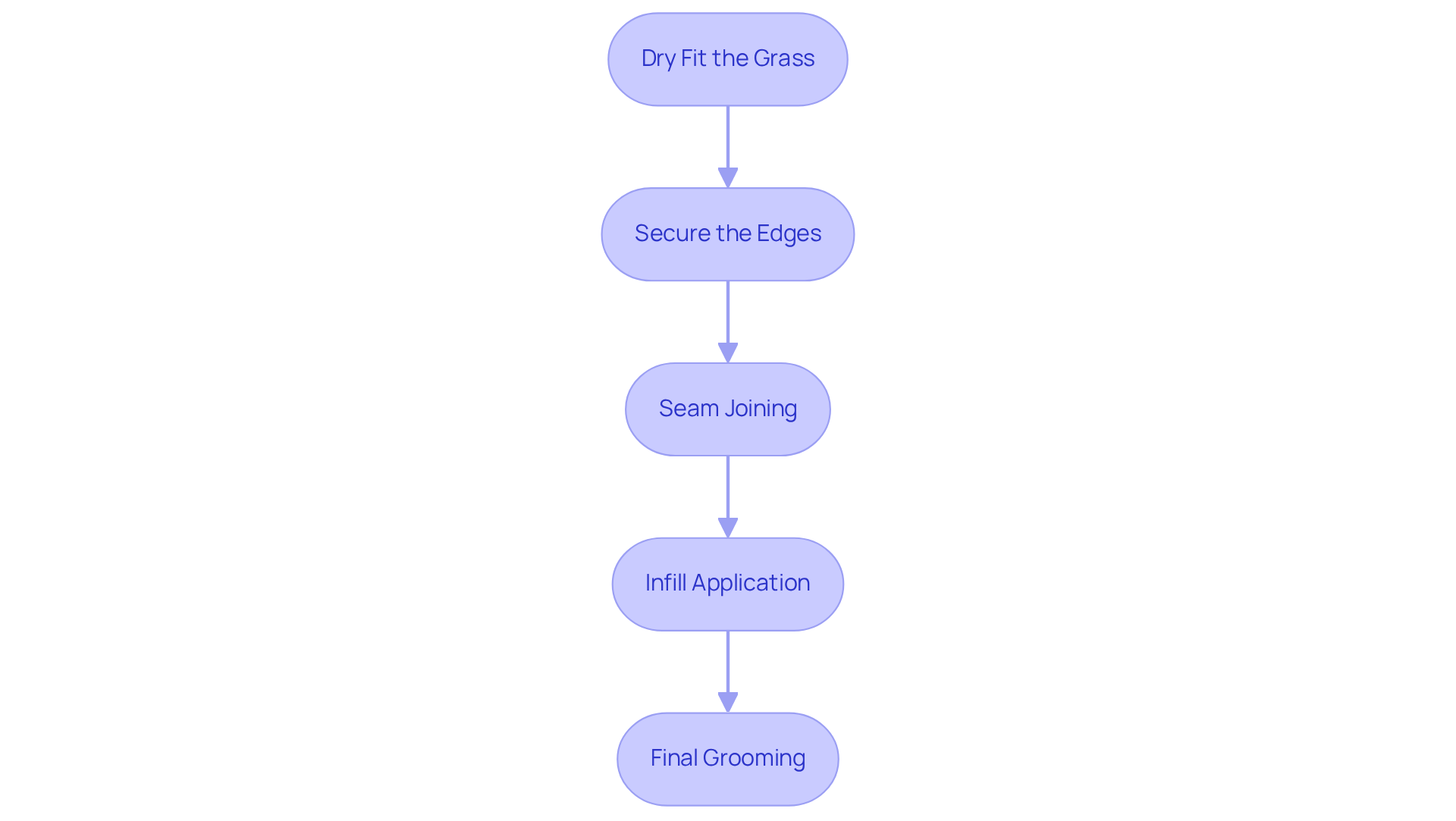

Implement Precise Installation Techniques

To achieve a flawless installation of artificial grass, follow these essential techniques:

-

Dry Fit the Grass: Begin by laying out the grass in the desired area to check for fit and make any necessary adjustments. This step allows you to visualize the final look and ensures proper alignment.

-

Secure the Edges: Use landscaping stakes or adhesive to secure the edges of the turf. This prevents shifting and maintains the integrity of the installation. It is crucial to space the stakes 6 to 8 inches apart to avoid fraying and shifting over time.

-

Seam Joining: When connecting two pieces of grass, ensure that the fibers are aligned in the same direction for a natural appearance. Use seam tape and adhesive to secure the seams, pressing firmly to eliminate gaps. Attention to seam placement is vital, as poorly installed seams can lead to a disjointed look and affect the overall aesthetic.

-

Infill Application: After laying the grass, apply an infill material such as sand or rubber granules. This helps weigh down the grass, supports the blades, and enhances drainage. Proper infill application is essential to prevent matted grass and ensure longevity.

-

Final Grooming: Use a stiff-bristled broom to brush the grass fibers upright, giving it a natural look. This final touch enhances the overall appearance and ensures that the grass looks its best. Regular upkeep, including brushing against the natural grain, will keep the turf looking fresh and vibrant.

By implementing these methods, you can achieve a professional-quality installation that meets high standards, ensuring your synthetic turf remains attractive and functional for years to come with the use of aggregate for artificial grass.

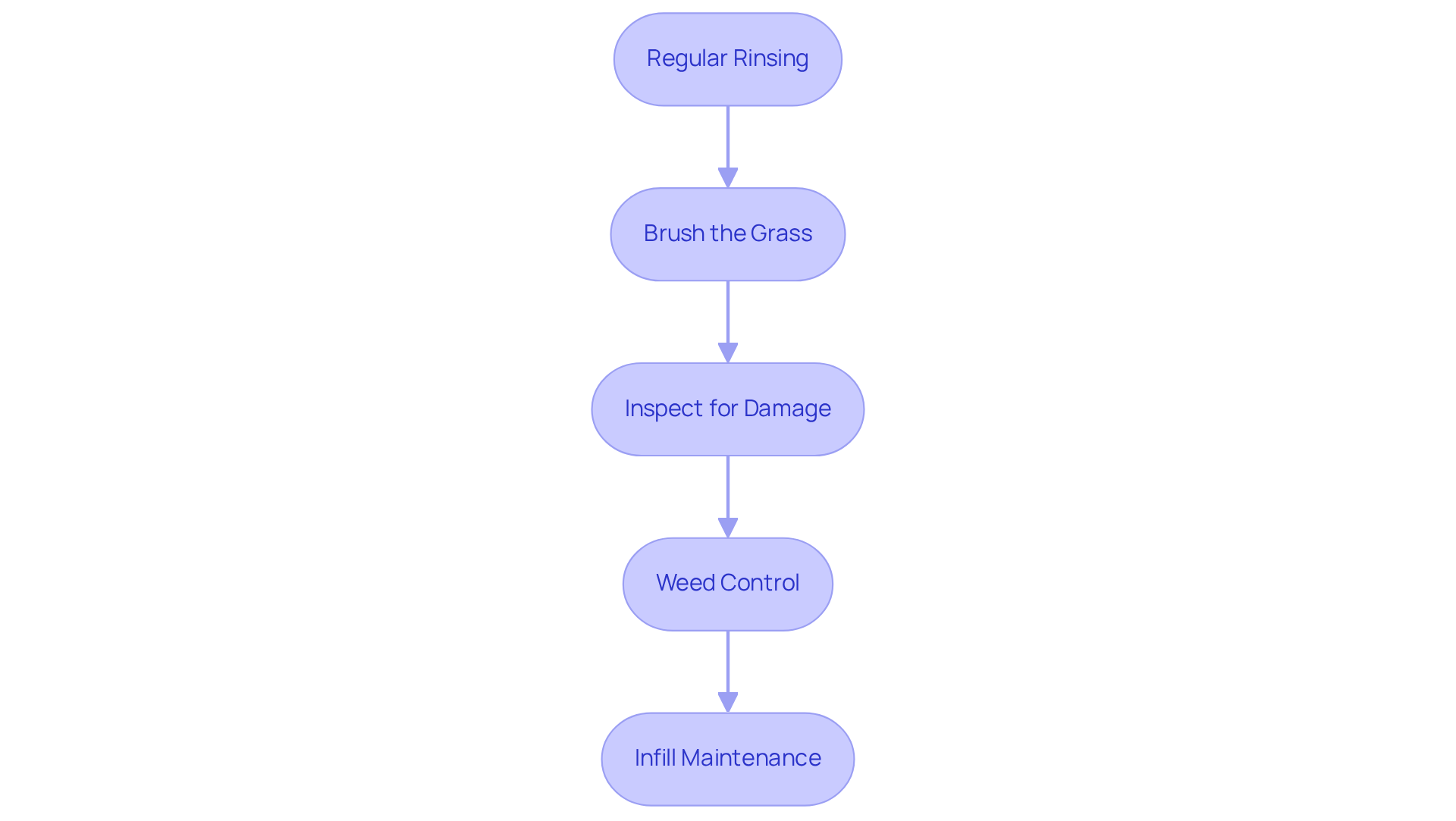

Maintain Your Aggregate and Turf for Longevity

To keep your artificial grass and its underlying aggregate in optimal condition, follow these essential maintenance practices:

-

Regular Rinsing: Periodically rinse the grass with a hose, especially in areas frequented by pets. This practice effectively removes odors and debris, contributing to a cleaner environment. As noted by SGW, “Our staff is committed to providing the best experience possible for our clients,” highlighting the importance of regular maintenance.

-

Brush the Grass: Use a non-metal rake or a stiff broom to brush the fibers regularly. This action helps maintain the upright position of the blades and prevents matting, ensuring a lush appearance. Brad Timsit emphasizes that “performing simple maintenance steps helps preserve artificial turf and keep it looking great.”

-

Inspect for Damage: Conduct routine inspections for signs of wear, such as separating seams or shifting grass. Addressing these issues promptly can prevent more significant problems later on. Regular inspections are crucial, as demonstrated in the “Winter Care for Artificial Turf” case study, which illustrates how proper maintenance extends the lifespan of artificial grass installations.

-

Weed Control: Monitor for any weeds that may breach the weed barrier. Quick removal of these intruders is essential to prevent their spread and maintain the integrity of your area. Statistics show that weeds can sprout in the infill layer, making proactive weed management vital.

-

Infill Maintenance: Regularly check the levels of aggregate for artificial grass and replenish as necessary to uphold the grass’s performance and aesthetic appeal. Annual or biannual deep cleaning is recommended to maintain optimal conditions, ensuring your turf remains in excellent shape.

By implementing these maintenance strategies, you can significantly extend the lifespan of your artificial grass installation, ensuring it remains visually appealing and functional for years to come.

Conclusion

Choosing the right aggregate for artificial grass installation is essential for creating a durable and visually appealing lawn. Materials such as crushed stone, decomposed granite, and sand are critical for ensuring proper drainage, stability, and overall turf performance. By understanding the specific functions of each aggregate type, homeowners can make informed decisions that enhance the longevity and maintenance of their artificial grass.

Key steps in the installation process include:

- Proper base preparation

- Precise installation techniques

- Regular maintenance practices

From excavating the area and compacting the soil to securing the turf and conducting routine inspections, each action contributes to a professional-quality installation. Avoiding common pitfalls, such as improper compaction or using unsuitable materials, is crucial for preventing future issues.

Ultimately, investing time and effort into the right installation techniques and ongoing maintenance will yield a lush, green lawn that remains beautiful and functional for years. Embracing these best practices not only enhances the aesthetic appeal of outdoor spaces but also promotes sustainable living by reducing the need for water and chemical treatments. Take action today to elevate your artificial grass installation and enjoy the benefits of a well-maintained, vibrant lawn.

Frequently Asked Questions

What are the common types of aggregates used for artificial grass installation?

The most common types of aggregates for artificial grass installation include crushed stone, decomposed granite, and sand.

What is the purpose of crushed stone in the installation of artificial grass?

Crushed stone is used as a base layer, providing excellent drainage and stability. It allows water to pass through while supporting the grass and prevents pooling or waterlogging.

How does decomposed granite contribute to the installation of artificial grass?

Decomposed granite serves as a leveling layer on top of the crushed stone, offering a smooth surface for the grass and enhancing overall stability through proper compaction.

What role does sand play in the artificial grass installation process?

Sand is used as a top dressing to weigh down the turf and improve drainage. It fills spaces between larger aggregates, preventing uneven settling and maintaining a tidy surface.

What are some common mistakes to avoid when preparing the base for artificial grass?

Common mistakes include using inappropriate rock sizes and failing to compact materials properly, which can lead to instability and drainage issues.

How does choosing the right aggregate impact the performance of artificial grass?

Selecting the right aggregate enhances the installation process, ensures optimal turf performance over time, reduces maintenance needs, and prolongs the lifespan of the artificial grass.