Introduction

As synthetic grass gains popularity, homeowners in Kansas are uncovering the numerous advantages of a lush, low-maintenance lawn. This guide offers a clear, step-by-step method for installing synthetic grass, ensuring not only visual appeal but also durability and efficiency.

With various materials and techniques available, how can one guarantee a flawless installation that endures over time?

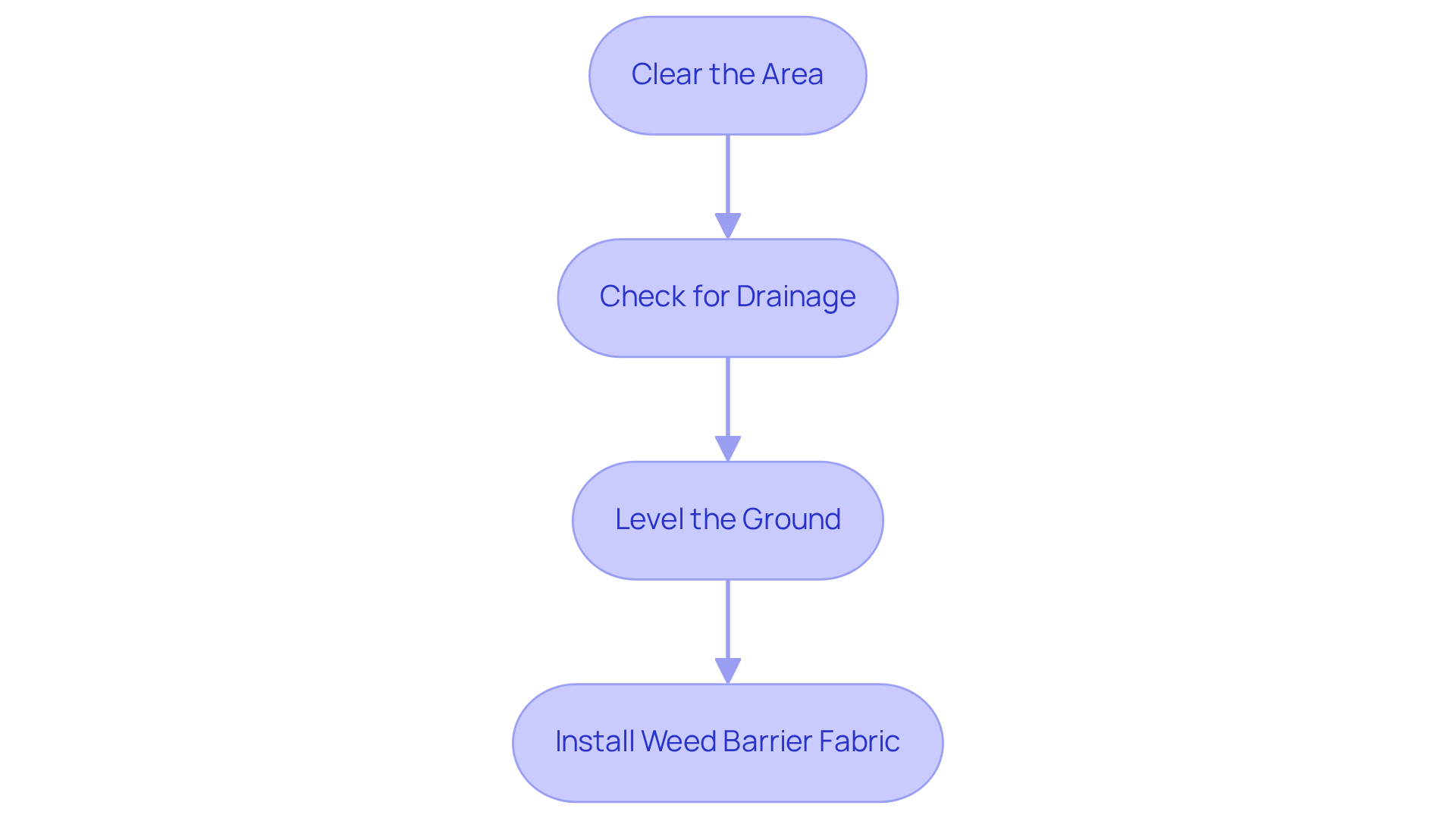

Prepare Your Installation Area

-

Clear the Area: Start by removing any existing grass, weeds, and debris from the installation site. Use a shovel or sod cutter to excavate the top layer of soil to a depth of 3 to 4 inches. This step is essential for establishing a solid foundation for your grass synthetic. Dick Bryant highlighted the importance of a thorough assessment of his requirements by Brock, underscoring the significance of this initial phase.

-

Check for Drainage: Evaluate the drainage capabilities of the area. If the ground appears too flat, consider grading it to create a slight slope away from structures. Proper drainage is crucial to prevent water pooling, which can compromise the integrity of your turf over time. Scott Sachse noted the professionalism of the crew, ensuring that such critical details were not overlooked during his setup.

-

Level the Ground: Utilize a rake to ensure the ground is level, filling in any low spots with soil to create an even surface. This attention to detail helps avoid bumps and dips in the final installation, contributing to a professional finish. Les Boatright emphasized Brock’s commitment to detail, which is vital for achieving a flawless result.

-

Install a weed barrier fabric to inhibit weed growth beneath the grass synthetic. This essential step not only maintains the aesthetic appeal of your grass but also protects its integrity, ensuring longevity and minimal maintenance. Trust Hall Turf to provide expert artificial turf solutions tailored to your Kansas home, as reflected in the positive experiences of our satisfied customers.

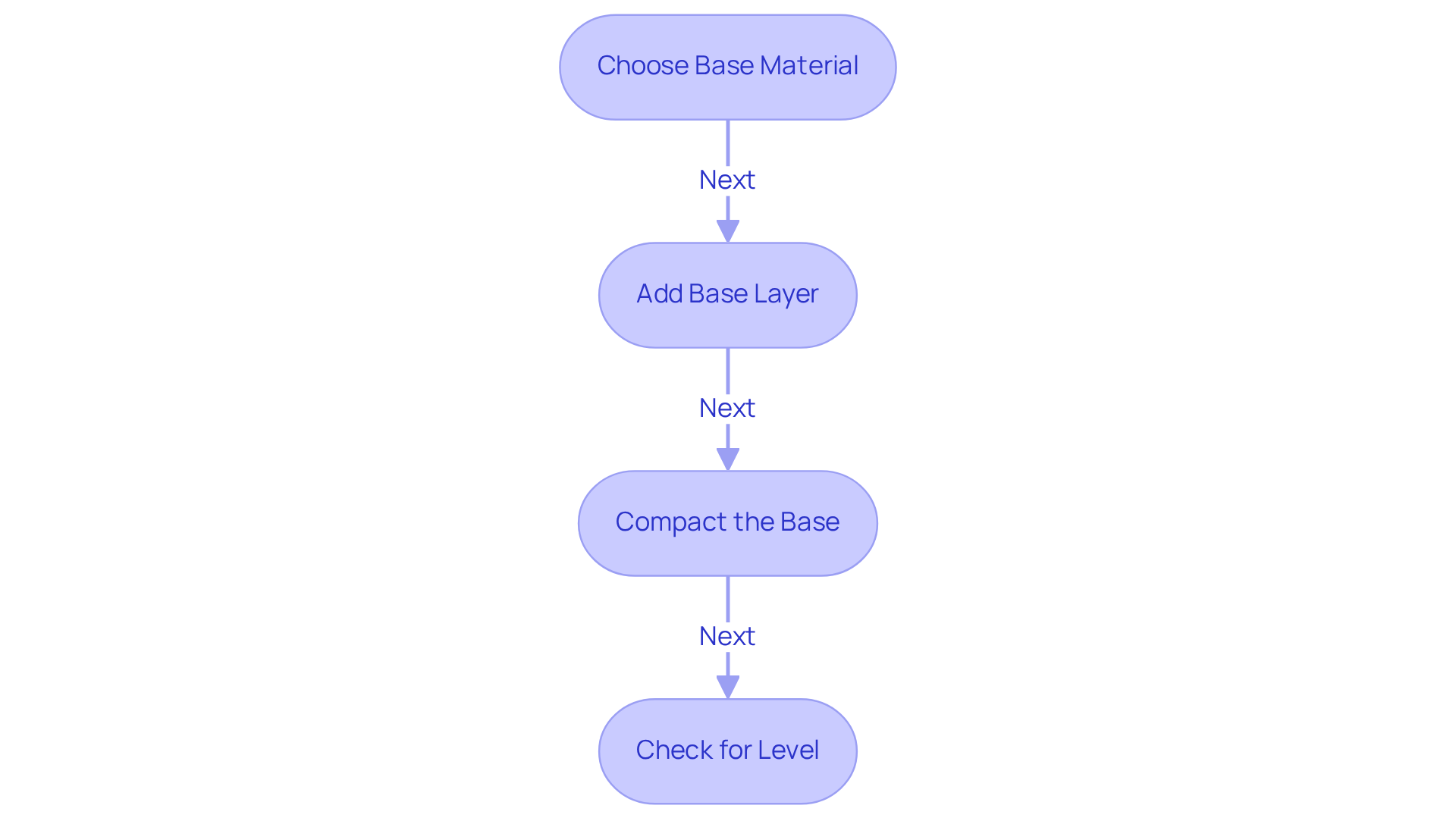

Build a Stable Base for Turf

-

Choose Base Material: Select a suitable base material, such as Class II road base or decomposed granite (DG). Both materials are recognized for their excellent drainage and stability. Class II road base should be installed in layers of 3 to 6 inches, making it particularly effective for high-traffic areas. In contrast, DG is ideal for decorative applications and should be installed in layers of 3 to 4 inches. As of 2025, the average installed cost for a DG base ranges from $1.50 to $3.00 per square foot.

-

Add Base Layer: Spread a 2-3 inch layer of the selected base material evenly across the installation area. Utilize a large rake to ensure an even distribution, which is crucial for proper drainage and support for the grass.

-

Compact the Base: Thoroughly compact the base material using a plate compactor. This step is essential, as proper compaction prevents settling and establishes a firm foundation for the turf. Aim for a compacted thickness of 2 to 4 inches, depending on the specific requirements of your setup.

-

Check for Level: After compacting, employ a level tool to verify the surface. Make any necessary adjustments to ensure a flat and even surface, which is vital for effective drainage and the longevity of your grass synthetic installation. Additionally, check for pooling after rain to identify any drainage issues early.

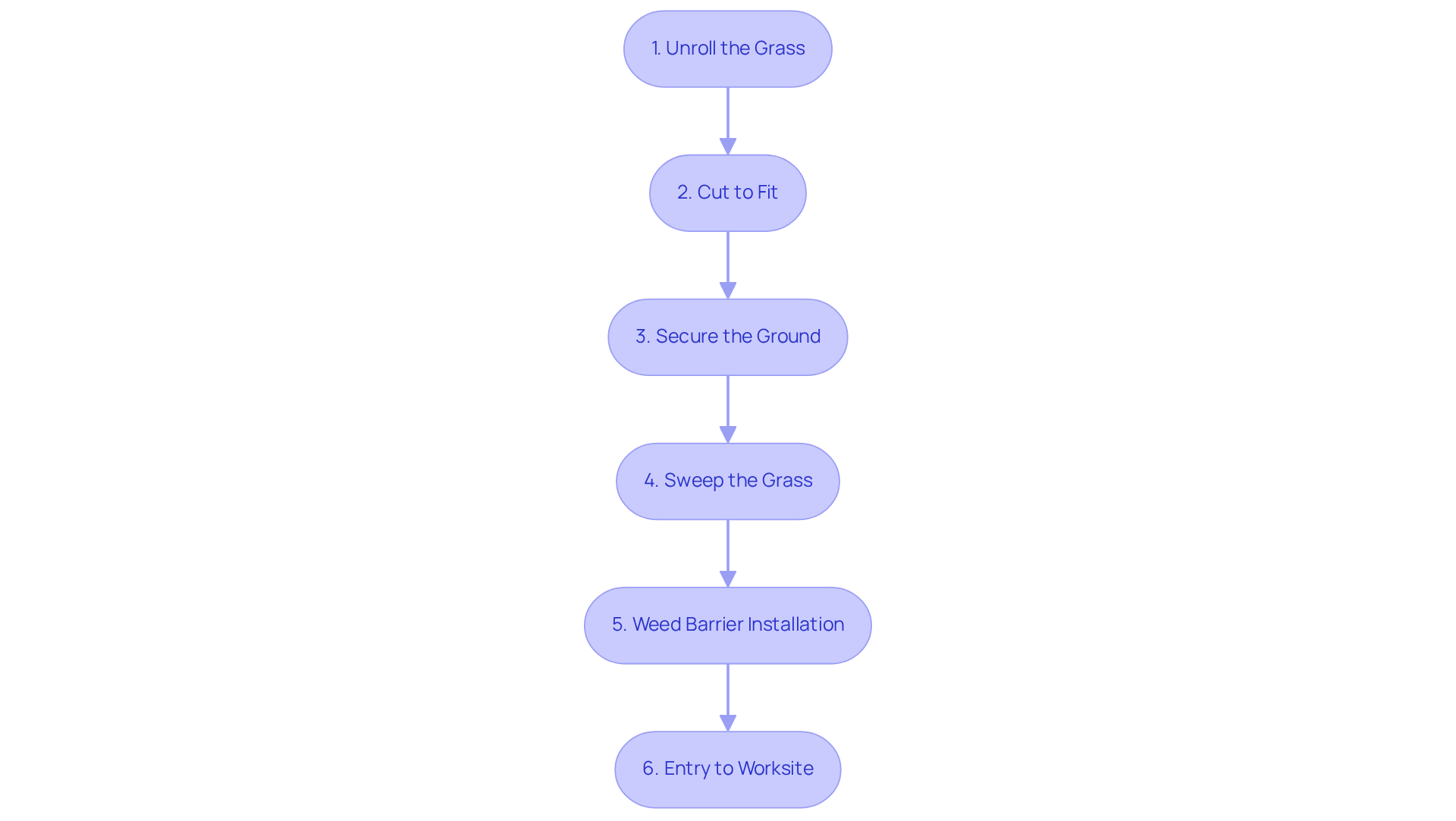

Lay Down the Synthetic Grass

-

Unroll the grass synthetic: Start by carefully unrolling the synthetic grass over the prepared base. Allow the grass to acclimate to the temperature for a few hours; this minimizes curling and ensures a smoother installation process. Hall Turf’s team, led by Brock, is recognized for their professionalism and meticulous attention to detail during this initial phase.

-

Cut to Fit: Use a utility knife to trim the edges of the grass, ensuring a perfect fit within the designated area. Pay close attention to aligning the seams of the grass pieces to achieve a seamless appearance, enhancing the overall aesthetic of your lawn. Brock’s expertise guarantees that this step is executed flawlessly, contributing to a polished final product.

-

Secure the Ground: To ensure stability, fasten the ground around the perimeter and along seams using landscape staples or galvanized nails. Space these fasteners approximately 6-8 inches apart, which is crucial for maintaining the integrity of the installation and preventing shifting over time. Clients have praised Hall Grass for their comprehensive strategy, which effectively secures the grass.

-

Sweep the Grass: After securing the grass, use a broom or power brush to lift the fibers. This step not only enhances the natural appearance of the grass but also aids in distributing the infill uniformly, resulting in a more realistic sensation underfoot. The Hall team is acknowledged for their meticulous attention to detail, ensuring that every aspect of the installation meets high standards.

-

Weed Barrier Installation: Consider installing a weed barrier before laying the grass synthetic to prevent natural grass from growing through the synthetic surface, ensuring a clean and low-maintenance lawn. This proactive measure is part of Hall’s comprehensive service offerings.

-

Entry to Worksite: Ensure that the setup location is easily accessible for workers, as this can significantly influence the setup timeline. Hall’s team is recognized for their punctuality and commitment to completing projects on schedule.

Statistics indicate that professional synthetic grass installations typically take between one to three days, depending on the size and complexity of the area. By following these steps, homeowners can expect a seamless and satisfying experience with Hall Turf’s expert solutions.

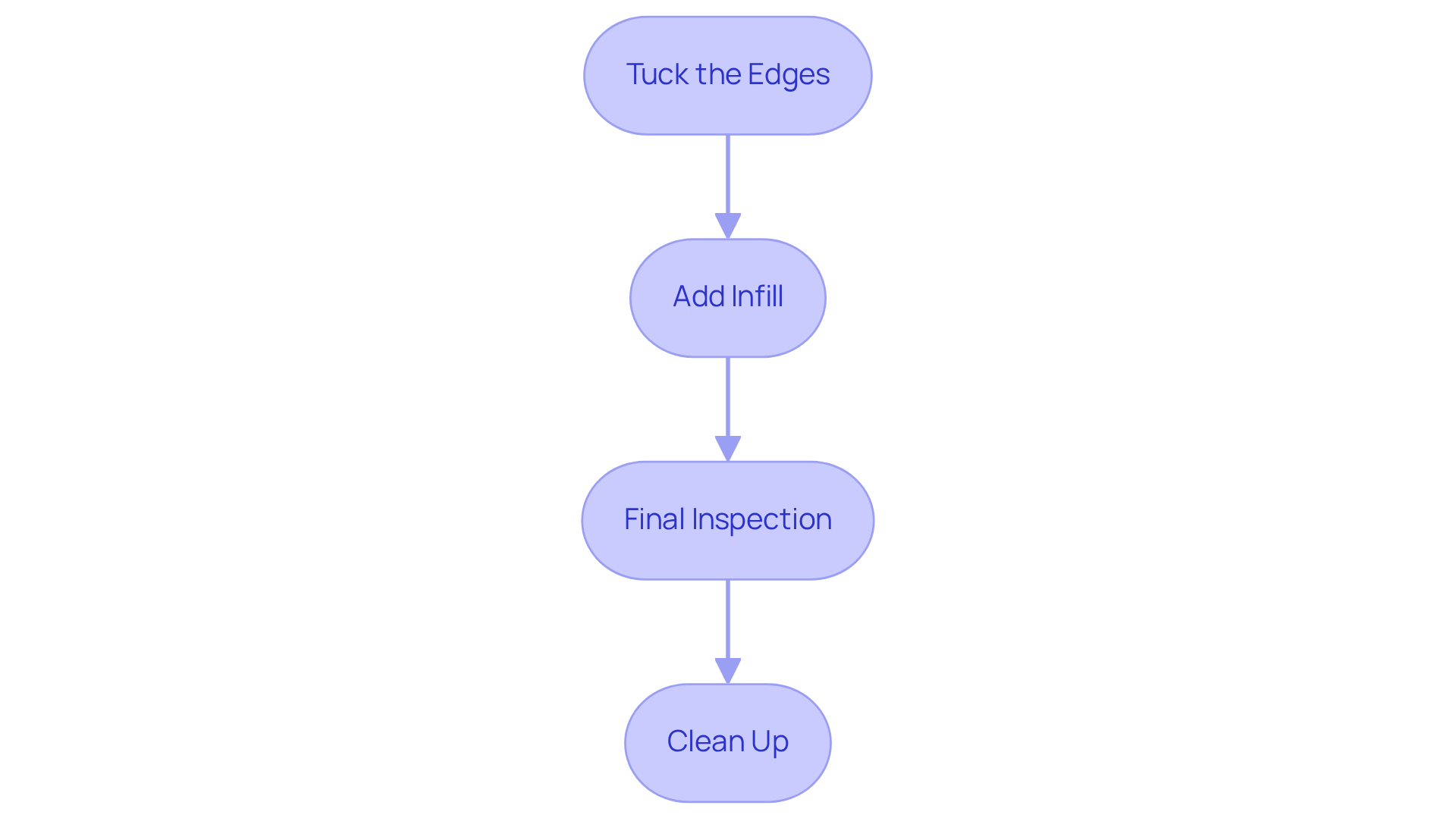

Secure and Finish the Installation

-

Tuck the Edges: Start by tucking the edges of the grass beneath any borders or hardscaping to achieve a polished finish. Using a carpet tucking tool will ensure a neat and professional edge, preventing any lifting or fraying over time.

-

Add Infill: Next, evenly distribute infill material, such as silica sand, Safeshell, or Envirofill, across the surface. This essential step provides necessary weight and stability, allowing grass blades to stand upright and enhancing the overall durability of the installation. Proper infill not only supports the grass structure but also improves drainage and reduces the risk of matting, which can lead to premature wear. For instance, Envirofill comes with a 16-year warranty, underscoring its durability and effectiveness in maintaining grass quality.

-

Final Inspection: Conduct a thorough walk-around of the installation to identify any loose areas or imperfections. Make adjustments as needed to ensure that each section is secure and visually appealing, thereby enhancing the durability of your grass. Remember, failing to use adequate infill can result in matting and bald spots, compromising the turf’s appearance and functionality.

-

Clean Up: Finally, remove any excess materials and debris from the setup site. Responsible disposal of waste will leave the area clean and tidy, enhancing the overall presentation of your new grass synthetic. Additionally, consider your budget when selecting infill, as different types vary significantly in price, impacting overall installation costs.

Conclusion

Installing synthetic grass can transform a Kansas home into a lush, low-maintenance oasis. Homeowners who follow the outlined steps can ensure a successful installation that enhances aesthetic appeal while providing a durable and functional lawn. The process begins with careful preparation of the installation area, highlighting the importance of a solid foundation and effective drainage to prevent future issues.

Key aspects of the installation include:

- Selecting the right base materials

- Ensuring proper leveling and compaction

- Meticulously laying down the synthetic grass

Each step, from tucking edges to adding infill, is crucial for achieving a polished and lasting finish. Insights from satisfied customers underscore the value of professional installation, which can save time and guarantee quality results.

Ultimately, investing time and effort into the installation process pays off in the long run. Homeowners are encouraged to embrace these best practices for installing synthetic grass, ensuring not only a beautiful lawn but also a space that is easy to maintain and enjoy for years to come.

Frequently Asked Questions

What is the first step in preparing the installation area for synthetic grass?

The first step is to clear the area by removing any existing grass, weeds, and debris. This involves excavating the top layer of soil to a depth of 3 to 4 inches to establish a solid foundation.

Why is checking for drainage important in the installation process?

Checking for drainage is important to prevent water pooling, which can compromise the integrity of the turf over time. If the ground is too flat, grading it to create a slight slope away from structures is recommended.

How can I ensure the ground is level before installing synthetic grass?

To ensure the ground is level, use a rake to create an even surface and fill in any low spots with soil. This attention to detail helps avoid bumps and dips in the final installation.

What is the purpose of installing a weed barrier fabric?

The purpose of installing a weed barrier fabric is to inhibit weed growth beneath the synthetic grass, maintaining its aesthetic appeal and protecting its integrity for longevity and minimal maintenance.

Who can provide expert artificial turf solutions in Kansas?

Trust Hall Turf to provide expert artificial turf solutions tailored to your Kansas home, as reflected in the positive experiences of satisfied customers.